Strandboulevarden cloudburst tunnel

Projects

Cloudburst tunnels and other climate change mitigation and adaptation measures for future-proofing urban and rural areas are complex construction projects. They generate a substantial need for sophisticated engineering surveying service. The cloudburst tunnel under Strandboulevarden in Copenhagen is no exception. LE34 is on site.

Client:

- Smet Group (main contractor for HOFOR)

Period:

- 2019 - ongoing

Services:

- As built-documentation

- Control measurements

- Setting out

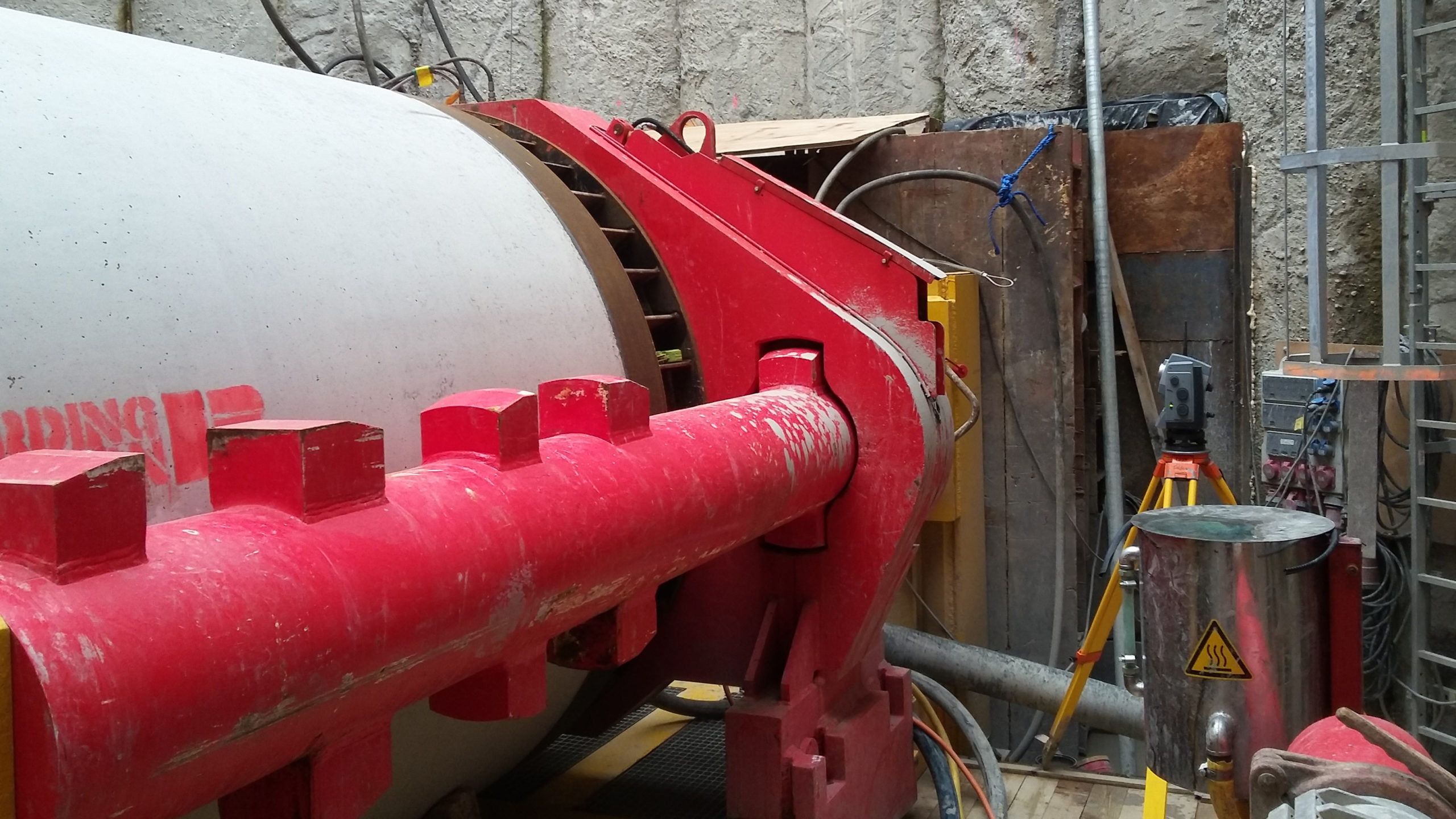

The cloudburst tunnel under Strandboulevarden and Gammel Kalkbrænderi Vej in Copenhagen will be bored deep into the earth. It is two metres in diameter and around 1,100 metres long.

Control measurements and as-built documentation ensure quality

As part of the cloud burst protection in Copenhagen HOFOR (Greater Copenhagen Utility) is constructing a cloudburst tunnel in Strandboulevarden in Østerbro. The tunnel will in the future help handle heavy rainfalls and cloud bursts which today causes the streets and basements to overflow around Strandboulevarden.

An important tool for ensuring that the cloudburst tunnel will actually be able to handle the large volumes of precipitation for which it is intended is documentation of the course of the finished tunnel. It is particularly important to document the downgrade of the tunnel tube, since the water must be able to flow through the tunnel and out into the harbour as quickly as planned. Therefore, LE34’s chartered land surveyors perform regular control measurements and create as-built documentation for this major tunnel project on an ongoing basis.

We work for the main contractor, Smet Group.

Pieter Hermans, Project Manager, Smet Group

“The execution of a tunnel is a very complex process involving many different disciplines and partners. Constant monitoring and control is therefore crucial during execution. With LE34 we have found a partner who, in addition to the necessary know-how, also has the necessary flexibility to quickly send people on site to carry out measurements and deliver the necessary documentation.”

Deep down

We use a total station in the cloudburst tunnel under Strandboulevarden. We perform precise measurements of the highest quality, using the total station’s sophisticated EDM-function.

Before: Setting out and as-built documentation ensure safe shafts

We are on site before, during and after the extensive work under ground.

Before tunnelling work can begin, four shafts are constructed to enable preparation of the crew and the extremely heavy drill for the challenging work. However, these shafts do not merely provide access routes for the crew and tunnel boring machine. They also help ensure the health and safety of anyone working in the drilling area. The shafts are deep and narrow, and they must be able to withstand invasive working methods and extreme pressure on their walls from the surroundings. Therefore, the contractor is required to work to high standards when constructing these.

As a provider of surveying and land management services, we contribute to this process by setting out and performing as-built inspections of the shafts’ secant walls, sheet piling walls and jet grout piles. Our as-built documentation provides the data on which inspection of the finished shafts is based, to ensure that they are constructed as required before drilling work begins.

During: Control measurements minimise risks

LE34 visits the site several times while drilling work is ongoing in order to perform control measurements. This is to ensure that the tunnel boring machine moves to precisely the right position.

Performing control measurements during the course of the project provides the client and the contractor performing the drilling (Smet Group) with documentation of the actual conditions and enables them to rectify any inadequacies at an early stage of the process.

After: Highly precise as-built documentation

The cloudburst tunnel will be bored in three stages. Once each stage of the tunnel tube is complete, we climb down under the ground again with our equipment – this time to perform as-built documentation of the actual course and downgrade of the finished tunnel tube.

Mario Švarc, chartered land surveyor, LE34

“We work in a 12-metre-deep shaft as well as inside the tunnel tube, but the available fix points are up at ground level and outside the drilling area. So we use prisms in various locations – at ground level as well as on the edge and at the bottom of the shaft. This enables us to perform a number of measurements and connect these in a datum grid, which we then use to verify the measurements we make inside the actual tunnel tube.”

Extensive experience in performing measurements in poorly accessible places

Over the course of many decades, LE34 has built up extensive experience in complex control measurements and as-built documentation for major construction projects, the metro, tunnels, harbour piers and building projects. Places that are difficult to access – such as the bottom of a 12-metre-deep shaft or inside a tunnel tube – are no problem: our staff have both the techniques and precision at their fingertips.

We use a total station in the cloudburst tunnel under Strandboulevarden. We perform precise measurements of the highest quality, using the total station’s sophisticated EDM-function (ultra high-precision distance measuring unit) and an angular accuracy of under 0.5 seconds in order to secure the quality.

Richard Lindquist Capion, chartered land surveyor and head of department, LE34

“There are many different disciplines involved in creating a cloudburst tunnel , and there are lots of people on site whose work needs to be coordinated. LE34 will therefore always be ready to visit the cloudburst tunnel at short notice, as soon as it’s time to perform the next measurements, so that the next phase of the construction work can start once we’ve completed our measurements and calculations.”

Contact us

Richard Lindquist Capion

Chartered land surveyor and head of department,

LE34 Copenhagen

Tlf. +45 7733 2172

rlc@le34.dk